How the coronavirus pandemic inspired Taylor's American Dream acoustic series

The surprising story behind the new acoustic line-up, and why it's fundamental to the company's history

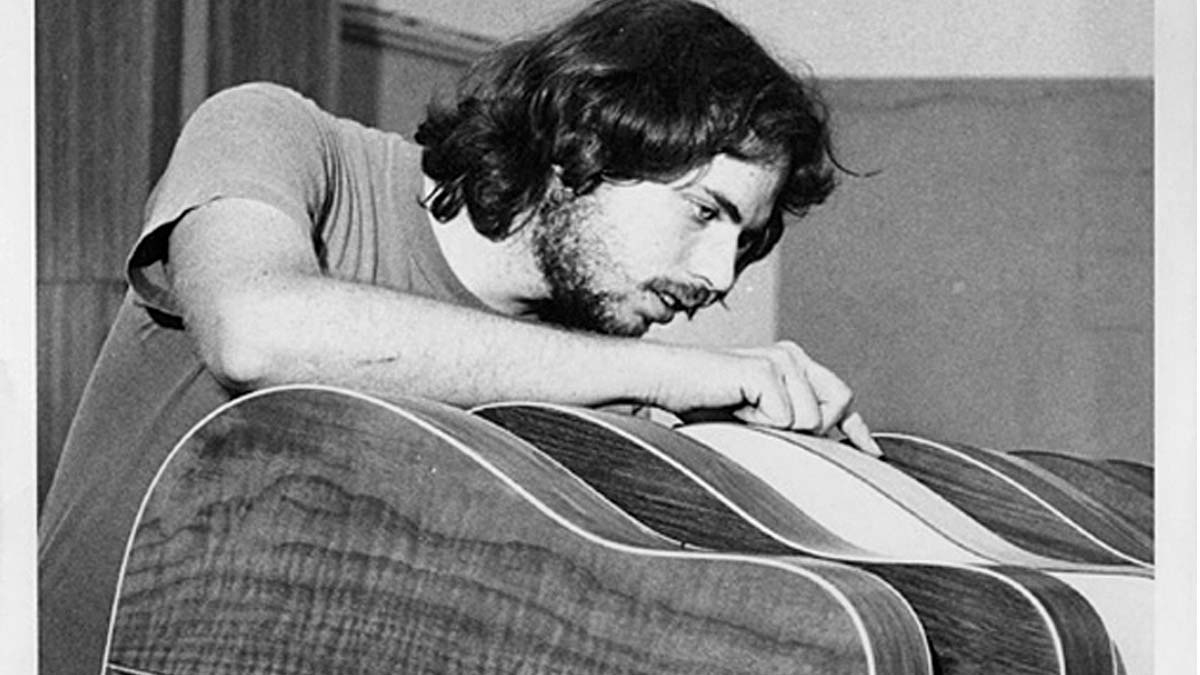

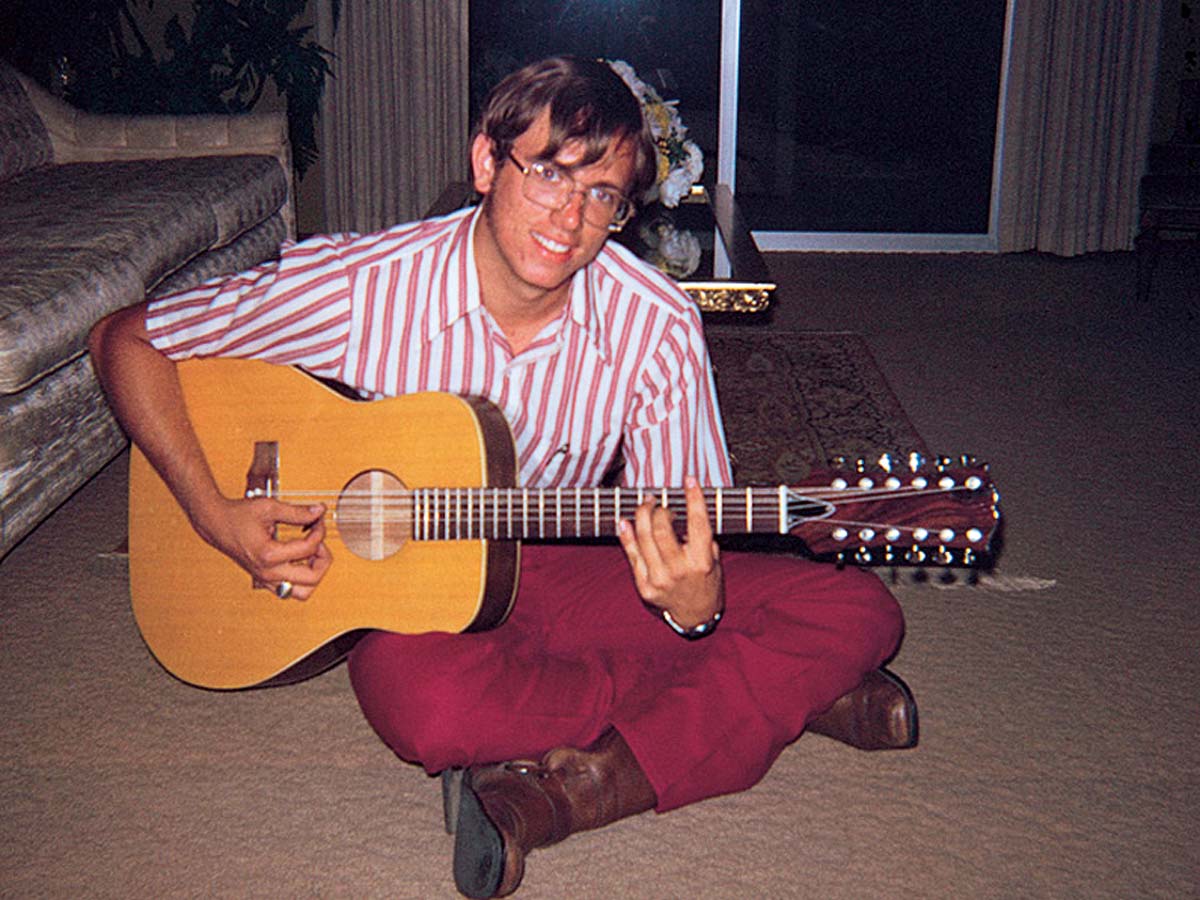

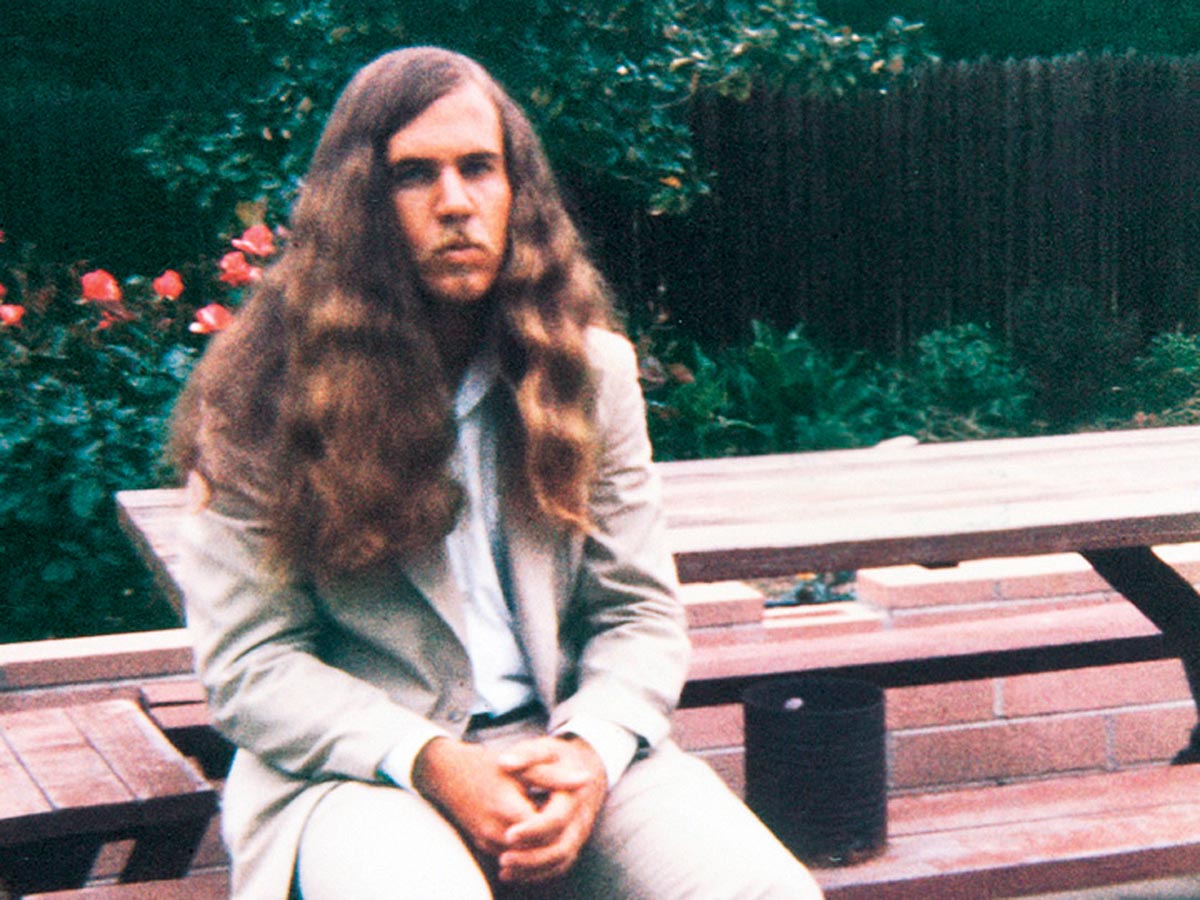

Taylor Guitars officially started on 15 October 1974. Bob Taylor and his partners, Kurt Listug and Steve Schemmer, had purchased the store where they worked building guitars – the American Dream – from owner Sam Radding.

They found they couldn’t actually use the name at the time because Sam’s brother who ran an American Dream retail outlet objected, so originally the venture ran under the title Westland Music Company. But they still needed a name for the guitars that they planned to make.

“I can see the three of us sitting around in the shop,” remembers Bob today, “Kurt, Steve and myself. ‘What are we going to call the guitars?’ It was quite a discussion. See, Kurt and Steve grew up across the street from each other and they were planning to buy this American Dream company but Kurt’s dad wouldn’t loan him any money to do it unless he brought someone in that actually knew how to build a guitar,” laughs Bob.

“So they said to me, ‘We can’t get the money to buy unless we have you as a partner so we want you in – but we don’t really want you in. So we’re going have 35 per cent each and you get 30 per cent. That way we have control over you.’ Those words were said. I simply said, ‘Yeah, that’s fine!’ I mean I was 19, they were 21.

Kurt and I have good chemistry and that’s not anything you can design

“Kurt thought a family name was good: ‘Taylor is good but we’re not so sure because we’re afraid of ego problems down the road.’ Kurt finally said, ‘Martin is good family name and Taylor is a good strong name.’ I mean, we said, ‘Listug might be good if we were making drums – no-one can say ‘Lustig’ as it’s pronounced, they always say ‘Listug’, how it’s spelt. And Schemmer, well, I mean…’

“So it was agreed that Taylor was a good name and although it could develop into a ‘problem’ we were going to take a chance on it. Kurt and Steve kind of acquiesced on it. Kurt did see the light though and I think it was one of the first signals that Kurt and I could arrive at a conclusion in agreement on something.

“And as the years went on, the three of us just noticed that Kurt and I would see eye to eye. Steve, well, you’d have to drag him into it. It’s just personality, chemistry. Kurt and I have good chemistry and that’s not anything you can design.”

Get The Pick Newsletter

All the latest guitar news, interviews, lessons, reviews, deals and more, direct to your inbox!

We went from making 700 guitars a day to making no guitars a day. There was really no end in sight

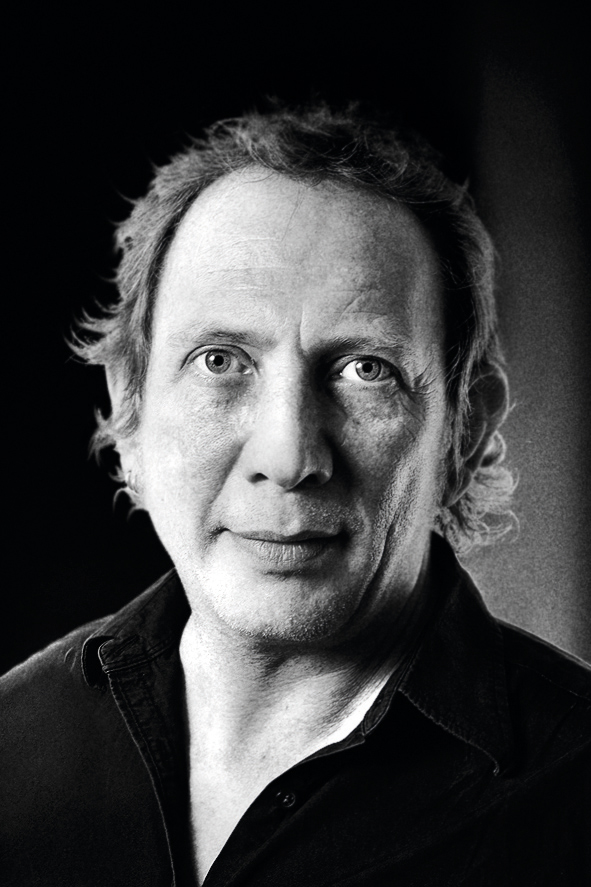

Fast-forward nearly 46 years and Taylor sits at the forefront of acoustic guitar making. But like everyone else, the recent pandemic turned everything on its head.

“We went from making 700 guitars a day to making no guitars a day,” states Bob somberly. “There was really no end in sight. Tecate [the location of Taylor’s Mexican factory] was closed – we didn’t know for how long. Our factory here in El Cajon was closed, although our engineers were working and we were shipping guitars we had built for stock.

“Let’s imagine that Tecate doesn’t open for a long time, what if we have to replace some of the price range we make in Mexico with the price range here in the USA? How in the world are we going to do that? How are we going to offer a guitar made in the USA that gets at least into the 200 Series Mexican-made price range?”

At some speed a plan formed to create a stop-gap mini range, made in the USA, as Bob explains: “We started to think of a way to make a guitar with the method that had really started with the Baby Taylor 25 years ago, the GS Mini, and the Academy series that’s worked its way up into Andy Power’s Builder’s Editions where the treatment might all be about the soft edges.

“The purflings are on the top and the top is very precisely located, which allows us to make these guitars without the binding step. Then there are the satin finishes, too.

“But there was another component: in El Cajon we have an incredible build-up of… let’s take necks, for example. We cut our neck shafts and here’s one with the smallest cosmetic defect in it. Set it aside, don’t use it. I’d been on a warehouse clear-up for a really long time and there is a lot of wood we weren’t currently using.

The orders came in like there’s no tomorrow. We’ve never seen anything like it. You know, we have 95,000 guitars on order right now

“Andy had started thinking about how we make this guitar and I said, ‘What about if we have, how would you say, built-in ‘American character’ right from the start, you know?’ Some of this wood we’d set aside because of a raw flaw here and there. Or maybe it’s a species we’re no longer using, like ovangkol – I think we had 6,000 to 7,000 guitars’ worth of back and sides of that.

“So, we thought, maybe we could harness the power of all that material and the power of our factory that is always eager and we could design this guitar. “And then we thought, ‘What are going to call it?’ That’s when we went back to our original name where we’d started, American Dream. We’ve actually kept that trademark alive for the past 45 years.

To do that, once every 10 years we have to sell an American Dream guitar. So we’d find a dealer, make two guitars, an American Dream model with a label in it, and that meant we could still maintain our trademark. So we had the name there, all ready to go.” Ironically – and we’ve had similar reports from numerous large-scale guitar makers – the lockdown created quite a spike in sales.

“The orders came in like there’s no tomorrow,” exclaims Bob. “We’ve never seen anything like it. You know, we have 95,000 guitars on order right now. We usually keep around 30,000 guitars in stock, which allows us to fulfil our promise of restocking your store.

“But we took that stock down to the walls. Someone would come into your office, point at a guitar and say, ‘You playing that thing? If not, we could sell it.’” A commercial tie-up with PlayStation and The Last of Us Part II game hasn’t hindered demand, either.

“I don’t play videogames,” says Bob, “but I understand this is the most popular one in the world. So, yes, we did do a tie-up and they prominently displayed our guitar – we ended up making a GS-Mini and that had trade dress from that game, and also a 314. Those were used in the game and people bought them. Sony sold them direct; we sold them to Sony. We sold a lot of them!

“It’s amazing to see how our guitars get into current culture that way. I’m still stunned that our guitars get used in so many places like that – they’ve just wiggled their way into everyday life.”

And despite the reasons for their creation, Bob is confident that the American Dream guitars will still be offered when the pandemic subsides.

“I think we will because one thing that I’m delighted about is the American Dream concept is a way that we can use more materials. As guitar players, we’ve been systematically taught to look at near-perfect pieces of wood. The American Dream concept is a way to, let’s say, cook with what we have in the refrigerator.

As guitar players, we’ve been systematically taught to look at near-perfect pieces of wood. The American Dream concept is a way to, let’s say, cook with what we have in the refrigerator

“It’s like one of those TV shows where a top chef knocks on your door to cook you great meal and you go, ‘But I haven’t got any ingredients in the refrigerator.’ He goes, ‘You’ve got plenty: just sit down and I’ll do it.’ Half an hour later you go, ‘Holy smokes! You made that from what I had in my refrigerator? I didn’t think I had anything.’

“So American Dream also fits my environmental work because one of the first things about this journey of sustainability is not to waste anything. It’s like using ebony with some colour and stripes in it. People go, ‘What are you doing?’ You have to go on tour and tell people about it.

“I’m knee-deep in the water and have paid the dues, so to speak, so I think I’m able to talk about making good guitars out of – I’m going to say – more humble materials, or materials that don’t make the cut for what we normally do. I think American Dream will serve to do that. It’s just a way for a top chef to cook from the refrigerator.”

For more historical detail and plenty of cracking stories, Bob Taylor’s Guitar Lessons: A Life's Journey Turning Passion into Business is recommended reading.

Dave Burrluck is one of the world’s most experienced guitar journalists, who started writing back in the '80s for International Musician and Recording World, co-founded The Guitar Magazine and has been the Gear Reviews Editor of Guitarist magazine for the past two decades. Along the way, Dave has been the sole author of The PRS Guitar Book and The Player's Guide to Guitar Maintenance as well as contributing to numerous other books on the electric guitar. Dave is an active gigging and recording musician and still finds time to make, repair and mod guitars, not least for Guitarist’s The Mod Squad.

“Among the most sought-after of all rhythm guitars… a power and projection unsurpassed by any other archtop”: Stromberg has made a long-awaited comeback, and we got our hands on its new Master 400 – a holy grail archtop with a price to match

The heaviest acoustic guitar ever made? Two budding builders craft an acoustic entirely from concrete because they “thought the idea was really funny”